“Every Mountain brand plastwood sheet has passed the quality test in every step. From the process of mixing raw materials to obtaining plastwood sheets Rest assured that all sheets meet TIS and ISO9001 standards.”

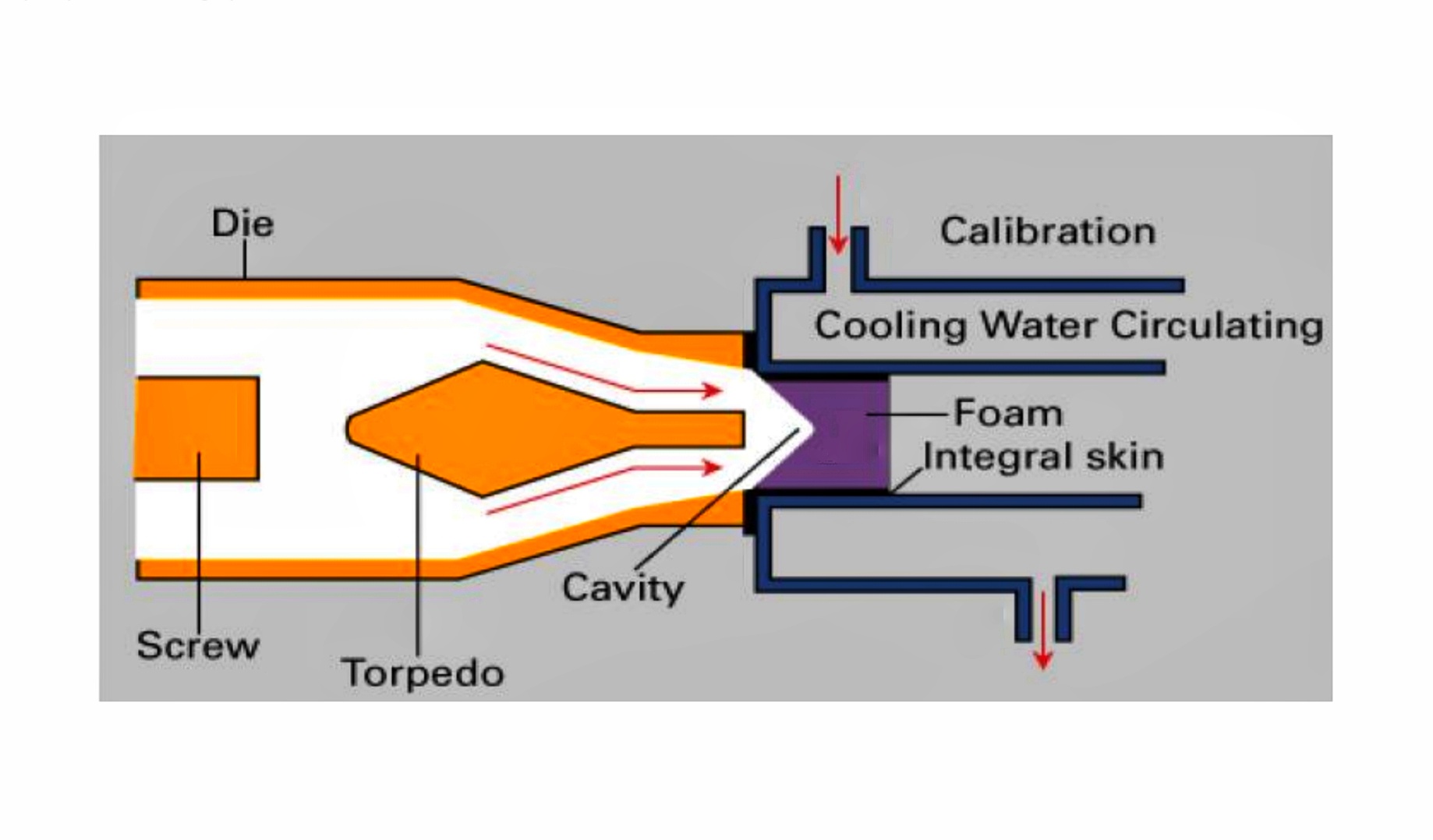

Plastwood sheet products Made from high-quality plastic (Unplasticized Polyvinyl Chloride or uPVC) mixed with the additives and then molded by extrusion process and then sandwiched together like a sandwich (Celuka) or pressed with a roller (Free-Form) and cast sheet To harden quickly (Shocking) with water or air Resulting in a sheet that has a particularly hard surface on both sides As well as having the core material of PVC foam hard, fine and tight, without any air cavity

Flat sheets of different models will use different production technologies. Resulting in a variety of products suitable for each type of use as follows

Model | Production Technology | Production Process

|

CT | Celuka Foam | It is a technology from Germany The substance will pass through the die with the middle lip and shocking with cold to make the material together and compress. Resulting in a high-density product The skin is smooth, shiny and very strong. Suitable for external work, can plan the surface to be adjusted along the edges of the furniture. High impact strength. It can repeatedly screw, not easily broken. |

LN | Semi Celuka Foam | It is a technology in which the substance will pass through the die with a middle lip and perform shocking at normal temperatures so that the material will stick together with compression, resulting in a product of a certain density Suitable for interior decoration of CNC furniture.

|

PT (Equivalent to TIS) PS TG | Co-Extrusion | Which the substance will pass through die head without lip in the middle The texture is smooth, shiny and hard. Each model is produced in a different density to suit the type of work and budget of the user.

|